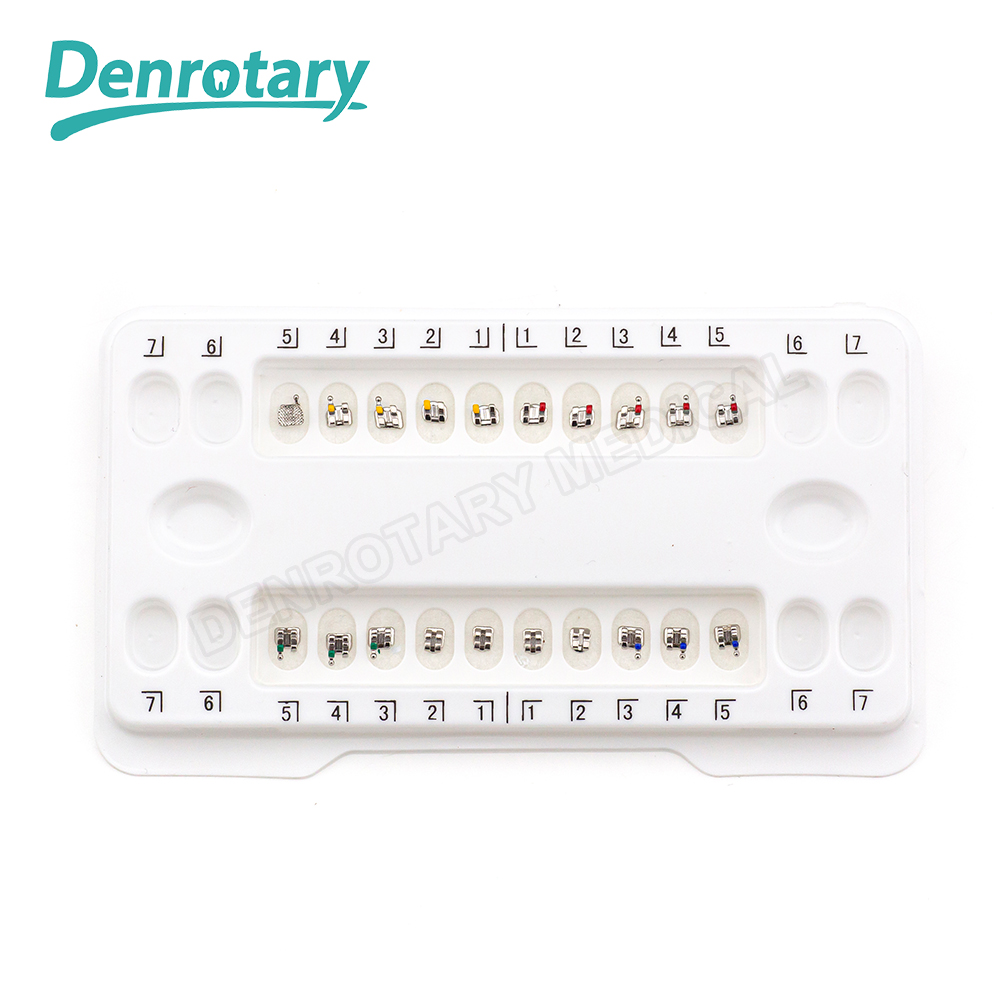

Ultra-low profile monoblock brackets are compact, single-piece components used in various engineering fields. Their design maximizes space efficiency while ensuring strength. You will find these brackets crucial for applications where weight and size matter, such as in Orthodontic Monoblock Brackets and high-performance machinery.

Key Takeaways

- Ultra-low profile monoblock brackets maximize space efficiency while ensuring strength, making them essential in industries like aerospace and orthodontics.

- Choosing the right materials, such as stainless steel or titanium, significantly impacts the strength, durability, and performance of the brackets.

- Implementing quality control measures, like dimensional and material testing, ensures that each bracket meets strict specifications for reliability and safety.

Design Principles

Structural Integrity

When you design ultra-low profile monoblock brackets, you prioritize structural integrity. This means you ensure the bracket can withstand forces without bending or breaking. Engineers often use computer simulations to test how the bracket will perform under stress. By doing this, you can identify weak points and improve the design before production.

Weight Distribution

Weight distribution plays a crucial role in the effectiveness of these brackets. You want to distribute weight evenly to avoid stress concentrations. Uneven weight can lead to failure in critical applications. For example, in Orthodontic Monoblock Brackets, proper weight distribution helps maintain alignment and stability during treatment. Engineers often use advanced modeling techniques to analyze how weight affects the bracket’s performance.

Aesthetic Considerations

Aesthetics matter in engineering, especially in consumer products. You want your ultra-low profile monoblock brackets to look appealing while being functional. A sleek design can enhance the overall appearance of a product. Many engineers collaborate with designers to create brackets that not only perform well but also fit seamlessly into the product’s design. This attention to aesthetics can improve user satisfaction and marketability.

Material Selection

Selecting the right materials for ultra-low profile monoblock brackets is crucial. The materials you choose affect the bracket’s strength, durability, and overall performance. Here’s a closer look at the common materials used, their impact on performance, and their hypoallergenic properties.

Common Materials Used

You will find several materials commonly used in the production of ultra-low profile monoblock brackets. These include:

- Stainless Steel: Known for its strength and resistance to corrosion, stainless steel is a popular choice. It provides excellent durability in various environments.

- Titanium: This lightweight metal offers high strength-to-weight ratios. You often see titanium in applications where reducing weight is essential, such as in aerospace and orthodontics.

- Plastic Composites: These materials are lightweight and can be molded into complex shapes. They are often used in consumer electronics where aesthetics and weight are critical.

Impact on Performance

The choice of material significantly impacts the performance of ultra-low profile monoblock brackets. For instance, stainless steel brackets can handle high stress and provide long-lasting support. In contrast, titanium brackets excel in applications requiring minimal weight without sacrificing strength.

When it comes to Orthodontic Monoblock Brackets, the material choice directly influences treatment outcomes. A well-chosen material can enhance the bracket’s ability to maintain tooth alignment while ensuring patient comfort.

Hypoallergenic Properties

Hypoallergenic properties are vital, especially in medical and dental applications. You want to avoid materials that may cause allergic reactions.

- Titanium is an excellent option due to its biocompatibility. It rarely causes allergic reactions, making it suitable for orthodontic applications.

- Plastic composites can also be hypoallergenic, depending on their formulation. Always check the specifications to ensure they meet safety standards.

By selecting hypoallergenic materials, you enhance patient comfort and satisfaction, particularly in orthodontic treatments.

Manufacturing Processes

Manufacturing ultra-low profile monoblock brackets involves several key processes. Each step ensures that the final product meets the required standards for strength, durability, and aesthetics. Let’s explore these processes in detail.

Metal Injection Molding

Metal injection molding (MIM) is a popular method for producing ultra-low profile monoblock brackets. This process combines the versatility of plastic injection molding with the strength of metal. Here’s how it works:

- Feedstock Preparation: You start with a mixture of metal powder and a binding agent. This mixture forms a feedstock that can be injected into molds.

- Injection Molding: The feedstock is heated and injected into a mold under high pressure. This step shapes the bracket into its desired form.

- Debinding: After cooling, the binding agent is removed through a process called debinding. This step leaves behind a solid metal part.

- Sintering: Finally, you heat the part in a furnace to fuse the metal particles together. This step enhances the strength and density of the bracket.

MIM allows for complex shapes and tight tolerances, making it ideal for applications like Orthodontic Monoblock Brackets, where precision is crucial.

Surface Finishing Techniques

Surface finishing techniques play a vital role in the performance and appearance of ultra-low profile monoblock brackets. These techniques enhance durability and provide a polished look. Common methods include:

- Electropolishing: This technique removes surface imperfections and improves corrosion resistance. It gives the bracket a smooth, shiny finish.

- Anodizing: Anodizing adds a protective oxide layer to metal surfaces. This process can also introduce color, enhancing the aesthetic appeal of the brackets.

- Coating: Applying a coating can improve wear resistance and reduce friction. You might use coatings like Teflon or ceramic for specific applications.

These finishing techniques not only improve the look of the brackets but also extend their lifespan, making them suitable for demanding environments.

Quality Control Measures

Quality control is essential in the manufacturing of ultra-low profile monoblock brackets. You want to ensure that each bracket meets strict specifications. Here are some common quality control measures:

- Dimensional Inspection: You measure the dimensions of each bracket using precision tools. This step ensures that the brackets fit correctly in their intended applications.

- Material Testing: Testing the materials for strength and durability is crucial. You might conduct tensile tests or fatigue tests to assess performance.

- Visual Inspection: A thorough visual inspection helps identify any surface defects or inconsistencies. This step is vital for maintaining high aesthetic standards.

Implementing these quality control measures guarantees that the brackets perform reliably in various applications, including Orthodontic Monoblock Brackets.

Applications of Orthodontic Monoblock Brackets

Aerospace Industry

In the aerospace industry, you find ultra-low profile monoblock brackets essential for reducing weight without sacrificing strength. Engineers use these brackets to secure components in aircraft and spacecraft. Their compact design allows for efficient use of space, which is crucial in aviation. You can trust that these brackets help maintain structural integrity during flight.

Automotive Sector

The automotive sector also benefits from Orthodontic Monoblock Brackets. You see them used in various applications, from securing engine components to supporting interior structures. Their lightweight nature contributes to fuel efficiency. Additionally, their durability ensures that they can withstand harsh conditions, such as vibrations and temperature changes. This reliability makes them a preferred choice for modern vehicles.

Consumer Electronics

In consumer electronics, ultra-low profile monoblock brackets play a vital role in product design. You encounter them in smartphones, laptops, and other devices. These brackets help hold components securely while keeping the overall design sleek and lightweight. Their aesthetic appeal enhances the look of electronic devices, making them more attractive to consumers. You can appreciate how these brackets contribute to both functionality and style.

In summary, you see that ultra-low profile monoblock brackets combine structural integrity, weight distribution, and aesthetic design. These engineering principles enhance performance across various industries. Their material selection and manufacturing processes ensure durability and reliability. You can appreciate their vital role in modern applications, from aerospace to consumer electronics.

FAQ

What are ultra-low profile monoblock brackets used for?

You use ultra-low profile monoblock brackets in various industries, including aerospace, automotive, and consumer electronics, to secure components while minimizing weight and maximizing space.

How do material choices affect bracket performance?

Material choices directly impact strength, durability, and weight. For example, titanium offers high strength with low weight, making it ideal for demanding applications.

Are ultra-low profile monoblock brackets safe for medical use?

Yes, many brackets use hypoallergenic materials like titanium, ensuring safety and comfort for patients, especially in orthodontic applications. Always check material specifications for safety standards.

Post time: Oct-01-2025