Dental professionals rely on quality products for effective patient care. Therefore, finding Reliable Dental Suppliers for Orthodontic Brackets is crucial. This guide empowers professionals to make informed decisions when sourcing Orthodontic Brackets from Chinese manufacturers. It helps identify key factors for selecting suitable partners. For instance, some manufacturers specialize in advanced Self Ligating Brackets. A reliable dental supplier ensures consistent product standards. Professionals should also prioritize suppliers offering CE Certified Dental Brackets. Denrotary Orthodontic Brackets, for example, meet high quality benchmarks.

Key Takeaways

- Chinese manufacturers offer many types of orthodontic brackets, like metal, ceramic, and self-ligating options.

- These manufacturers follow strict international quality rules, such as ISO, CE, and FDA, to make sure products are safe and work well.

- Buying brackets in large amounts from Chinese suppliers can save money and ensure you always have enough products.

- Building long-term relationships with these suppliers helps you get good prices and reliable support.

- You can get custom-made brackets and private labeling services to fit your specific needs and build your brand.

The Landscape of Chinese Orthodontic Brackets Manufacturing

Advantages of Sourcing Orthodontic Brackets from China

Sourcing from China offers significant advantages for dental professionals. Intense competition among manufacturers drives innovation and cost-efficiency. Mature supply chains ensure smooth operations. Readily available raw materials reduce procurement costs and delays. A deep pool of skilled labor, experienced in medical device manufacturing, streamlines production. Proximity of suppliers and manufacturers within industrial clusters leads to shorter lead times and lower overall costs. Chinese manufacturers benefit from cost-effective labor and advanced machinery, which helps reduce production expenses. Large-scale production leads to economies of scale. Buyers can also leverage bulk orders and tiered pricing, further enhancing affordability.

Key Trends in Orthodontic Brackets Production

Chinese manufacturers actively invest in modern production techniques and continuous research and development for new technologies and materials. They introduce advanced international production equipment. Many employ laser cold welding processes for metal brackets, ensuring high welding strength and precise bracket data. Manufacturers utilize advanced machinery and equipment for superior efficiency and consistent product quality. They also use CAD/CAM and 3D printing for precise and unique bracket designs, enabling customization for different patient cases. The industry explores new materials for improved aesthetics or enhanced biocompatibility.

Regulatory Standards for Chinese Orthodontic Brackets

Chinese manufacturers adhere to stringent regulatory standards, ensuring product safety and efficacy. They often comply with international quality standards such as ISO, CE, and FDA listings. This commitment reflects a dedication to producing high-quality medical devices. Companies implement robust in-house quality control measures throughout the manufacturing process. They also prioritize material sourcing and traceability, providing transparency and confidence in their products. These regulatory frameworks ensure that all Orthodontic Brackets meet global benchmarks for performance and patient safety.

Top-Rated Chinese Orthodontic Brackets Suppliers for 2026

Selecting the right supplier is paramount for dental practices. This section highlights leading Chinese manufacturers known for their quality, innovation, and reliability in the Orthodontic Brackets market. These companies consistently meet global standards and offer diverse product lines.

Foshan Vimel: Durable Metal and Ceramic Orthodontic Brackets

Foshan Vimel establishes itself as a prominent supplier of durable metal and ceramic orthodontic solutions. The company focuses on manufacturing brackets that withstand the rigors of orthodontic treatment. Their metal brackets feature robust construction, ensuring longevity and consistent performance throughout the treatment period. For patients seeking aesthetic options, Foshan Vimel offers ceramic brackets. These brackets provide excellent clarity and stain resistance, blending seamlessly with natural tooth color. Both metal and ceramic options undergo rigorous quality checks. This ensures they meet high standards for strength, precision, and patient safety. Dental professionals trust Foshan Vimel for reliable and effective orthodontic appliances.

Ningbo Denrotary Medical Apparatus Co., Ltd.: Enhancing Patient Comfort with Orthodontic Brackets

Ningbo Denrotary Medical Apparatus Co., Ltd. prioritizes patient comfort in its orthodontic bracket designs. They integrate advanced technology to optimize tooth movement while minimizing patient discomfort. The company crafts its brackets with smooth, rounded edges. This design significantly reduces irritation to the oral tissues. Their innovative designs also promote quicker tooth alignment. This leads to reduced treatment duration and enhanced patient satisfaction. Ningbo Denrotary uses state-of-the-art technology and premium materials. This ensures outstanding performance and superior patient comfort. Furthermore, they craft their products from high-quality materials for exceptional durability. The sleek and discreet design of their brackets also helps enhance patient confidence during treatment.

Shinye Orthodontic Products Co., Ltd.: Specialized Orthodontic Brackets R&D and Manufacturing

Shinye Orthodontic Products Co., Ltd. stands out for its specialized research and development capabilities and advanced manufacturing. The company is a key manufacturer in the ceramic brackets market, particularly in Asia. Shinye aims to disrupt traditional pricing models by offering cost-competitive alternatives. They primarily target emerging dental markets where price sensitivity is high. To address quality perceptions in premium Western markets, Shinye invests more in ISO certification and clinical validation studies. This commitment ensures their products meet international quality benchmarks. Shinye is also recognized as a key manufacturer in the Japan Dentistry Bracket Market. Manufacturers in this market are known for advanced technologies, strong R&D, and adherence to high manufacturing standards. Shinye focuses on delivering reliable, efficient, and cost-effective products. They often lead in setting industry trends and integrating smart, eco-friendly solutions. Their product offerings include a comprehensive range of ceramic brackets for orthodontics.

Brilliant Orthodontics (Hangzhou): Innovative Self-Ligating Orthodontic Brackets

Brilliant Orthodontics (Hangzhou) leads the industry with its innovative self-ligating orthodontic bracket systems. The company focuses on advanced designs that enhance treatment efficiency and patient comfort. They offer distinct product lines to meet diverse clinical needs. Their LOYAL Series Self Ligating Brackets provide reliable performance and ease of use for orthodontists. Additionally, the SHINE Series Self Ligating Brackets represent another advanced option, offering superior aesthetics and functionality. These self-ligating systems eliminate the need for elastic ligatures, which reduces friction and allows for faster tooth movement. This technology also simplifies chairside procedures, saving valuable clinical time. Patients benefit from fewer appointments and improved oral hygiene due to the absence of ligatures that can trap food particles. Brilliant Orthodontics consistently delivers high-quality, patient-centric solutions.

Protect Orthodontics: Leading Brand in Passive Self-Ligating Metal Orthodontic Brackets

Protect Orthodontics has established itself as a leading brand in passive self-ligating metal brackets. The company designs its brackets to offer exceptional control and efficiency throughout orthodontic treatment. Their passive self-ligating system features a low-friction mechanism. This design allows teeth to move more freely and comfortably. Orthodontists appreciate the precise control these brackets provide, which facilitates predictable treatment outcomes. Protect Orthodontics uses high-grade materials to ensure the durability and reliability of its products. The smooth, contoured design of their brackets also minimizes irritation to oral tissues, enhancing patient comfort. Dental professionals trust Protect Orthodontics for its commitment to quality and its innovative approach to orthodontic solutions.

EKSEN: CE Certified and FDA Listed Orthodontic Brackets

EKSEN stands as a reputable supplier known for its CE Certified and FDA Listed orthodontic products. This dual certification underscores EKSEN’s commitment to global quality and safety standards. CE certification confirms that their products meet European health, safety, and environmental protection requirements. FDA listing indicates compliance with the stringent regulations of the United States Food and Drug Administration. These certifications provide dental professionals with assurance regarding product safety, performance, and reliability. EKSEN manufactures a wide range of Orthodontic Brackets, ensuring each product adheres to rigorous quality control protocols. Their dedication to international compliance makes EKSEN a trusted choice for dental practices seeking high-quality, globally recognized orthodontic solutions.

Ensuring Quality and Reliability of Orthodontic Brackets

Dental professionals demand high-quality Orthodontic Brackets for effective patient treatment. Manufacturers implement strict quality assurance protocols. These protocols ensure product safety, performance, and consistency.

International Quality Standards for Orthodontic Brackets (ISO, CE, FDA)

Reputable manufacturers adhere to global quality standards. ISO 13485 outlines quality management system requirements for medical devices. This standard serves as a best practice for harmonizing Quality Management Systems (QMS). The FDA proposes to align its Quality System Regulation (QSR) with ISO 13485:2016. CE Marking under EU MDR requires a QMS compliant with Annex IX. Manufacturers apply for QMS assessment with a Notified Body. This body evaluates the QMS and technical documentation. A controlled design process is essential. The technical file must include General Safety and Performance Requirements (GSPR) and a full risk management file compliant with ISO 14971.

FDA 510(k) submissions require a complete Design History File (DHF). This file details system requirements, specifications, and risk management. The QMS must comply with the QSR (21 CFR 820). This regulation is also harmonizing with ISO 13485:2016. The submission demonstrates substantial equivalence to a legally marketed predicate device. For example, the FDA classifies orthodontic bands as follows:

| Product Code | Device | Regulation Description | Regulation Number | Device Class |

|---|---|---|---|---|

| DYO | Band, Material, Orthodontic | Orthodontic appliance and accessories. | 21 CFR 872.5410 | 1 (510k exempt) |

In-House Quality Control for Orthodontic Brackets

Manufacturers implement robust in-house quality control measures. These procedures ensure every product meets stringent specifications. Denrotary Medical, for instance, adheres strictly to medical regulations. They conduct rigorous testing to maintain high standards. They also utilize advanced German orthodontic production equipment. This commitment to advanced technology ensures precision and durability. G&H Orthodontics employs a “manufacturing-first approach.” They control the entire production process. This includes raw-material sourcing through final inspection. This end-to-end control guarantees consistent products and regulatory compliance.

Material Sourcing and Traceability for Orthodontic Brackets

Careful material sourcing is critical for product quality and patient safety. Manufacturers select high-grade, biocompatible materials. They establish strict supplier qualification processes. This ensures raw materials meet specific quality criteria. Traceability systems track materials from their origin to the final product. This allows manufacturers to identify and address any potential issues quickly. Comprehensive documentation supports material traceability. This practice provides transparency and builds confidence in the product’s integrity.

Understanding Orthodontic Brackets Product Offerings and Technology

Types of Orthodontic Brackets: Metal, Ceramic, Self-Ligating

Orthodontists choose from various types of Orthodontic Brackets to meet diverse patient needs. Each type offers distinct advantages and disadvantages. Metal brackets, typically stainless steel, remain popular due to their affordability and durability. However, they lack aesthetic appeal. Ceramic brackets provide a more aesthetic option; they are translucent, strong, and durable. Yet, they can be fragile and expensive. Plastic brackets offer comfort and cosmetic appeal but lack stiffness and strength. Self-ligating brackets, available in metal or ceramic, eliminate elastic bands. This design reduces friction and chair-side time. They promote more physiologically harmonious tooth movement. Lingual brackets offer excellent aesthetics by placing the appliance on the tongue side of teeth, but they can cause speech disruption and are more challenging to manage. Titanium brackets offer superior biocompatibility and lower friction, though they may show more plaque buildup and discoloration.

| Type of Bracket | Advantages | Disadvantages |

|---|---|---|

| Stainless Steel | Affordable, durable, widely used. | Not aesthetic, requires soldering, high modulus of elasticity. |

| Ceramic | Translucent, strong, durable, stable color, aesthetic. | Lacks ductility, expensive, fragile, stains easily, bulky. |

| Plastic | Comfortable, cosmetically appealing, less torque deformation. | Not strong, lacks stiffness, tie wing fracture, discoloration. |

| Self-Ligating | No elastic bands, less force needed, reduced chair-side time. | More expensive, clip/slide breakage risk, larger profile. |

| Lingual | Aesthetically appealing, protects teeth from over-calcification. | Speech disruption, occlusal interferences, tongue laceration. |

| Titanium | Good physical strength, easy to shape, superior biocompatibility, lower friction. | Plaque build-up, discoloration. |

Advanced Manufacturing Techniques for Orthodontic Brackets

Modern manufacturing processes significantly enhance bracket precision and efficiency. Metal Injection Molding (MIM), developed in the early 1980s, allows for mass production of complex brackets. It uses various alloys and offers cost-effectiveness. However, MIM can have intrinsic errors in slot accuracy. Computerized Numerical Control (CNC) offers greater precision. This method converts CAD designs into numerical data. A sophisticated milling machine then cuts a solid metal block. CNC produces more accurate bracket slots and offers better control over performance than MIM. It also allows for easy production of new designs by simply changing software, eliminating the need for new molds. Digital dentistry workflows, including CAD/CAM technologies, integrate seamlessly with these manufacturing methods. This integration reduces lead times and improves accuracy.

Material Science in Orthodontic Brackets Design

Material science drives innovation in bracket design, focusing on biocompatibility and mechanical properties. Researchers investigate bioceramics like HA and brushite films for their excellent biocompatibility. These materials resemble human teeth and bone. They overcome issues associated with metallic biomaterials, such as ion diffusion and toxicity. Mechanical properties, including fracture toughness, hardness, and shear bond strength, are crucial for bracket performance. Customized and 3D-printed bracket systems, developed using CAD/CAM, offer potential advantages. They can increase bracket slot precision and reduce treatment time. The field of biomaterials in orthodontics includes adhesives, metals (Titanium, Steel), elastomerics, and plastics/resins. Crystallographic studies help understand mechanisms affecting material properties. Atomic Force Microscopy (AFM) assesses physical material properties, providing insights into surface nano topography.

Pricing Strategies and Value Proposition for Orthodontic Brackets

Factors Influencing Orthodontic Brackets Pricing

Several factors significantly influence the pricing of Orthodontic Brackets. Material costs represent a primary driver. Price fluctuations in raw materials directly impact manufacturing expenses. Technological advancements in materials also affect pricing and performance. Different types of braces have varying costs due to the materials used and the complexity of their design. Manufacturing complexity, including advanced production techniques and innovative designs, also contributes to the final price. Furthermore, brand reputation plays a crucial role. Established brands often command higher prices due to perceived quality and reliability. Additional features, such as self-ligating mechanisms or aesthetic options, also increase costs.

Bulk Order Discounts for Orthodontic Brackets

Purchasing in bulk offers substantial financial advantages for dental practices. Manufacturers often provide significant discounts for large orders. These bulk purchasing agreements reduce the per-unit cost of brackets. This strategy improves overall cost-efficiency for clinics. It also ensures a consistent supply of materials, minimizing potential disruptions. Practices can leverage these discounts to manage their budgets more effectively.

Long-Term Partnership Benefits for Orthodontic Brackets Procurement

Establishing long-term partnerships with manufacturers provides benefits beyond immediate cost savings. These relationships often lead to preferential pricing and loyalty programs. This reduces overall procurement costs for practices. Reliable after-sales support is another key advantage. Manufacturers offer assistance with product issues, training, and maintenance. This dedicated support contributes to smooth practice operations. Long-term collaborations also foster trust and ensure a consistent supply of high-quality products.

OEM and Customization Services for Orthodontic Brackets

Benefits of Private Labeling Orthodontic Brackets

Private labeling offers significant advantages for dental practices and distributors. It allows companies to build their own brand identity. This differentiates their products in a competitive market. Private labeling also fosters customer loyalty. Businesses gain greater control over product specifications and quality. This ensures consistency with their brand standards. It can also lead to cost efficiencies through direct sourcing.

Design and Engineering Support for Custom Orthodontic Brackets

Manufacturers provide extensive design and engineering support for custom solutions. They begin with digital designs from patient malocclusion models. Technicians manipulate these models to align teeth to target positions. They position brackets from a library and adjust their features for optimal orthodontic outcomes. Manufacturers utilize rapid manufacturing equipment, such as Solidscape ModelMaker II systems. This creates investment-cast patterns with high resolution, surface finish, and precision. This process guarantees precision in arch wire slot tolerances, often within ±5 micron, for custom appliances.

Manufacturers also use multiple CAD software for product and mold design. This enables examination of part geometry and analysis simulation. It also helps forecast potential molding issues. They combine over 20 years of orthodontic design experience with 3D modeling. This expedites product development from concept to market. Their expertise in mold design focuses on quick, thorough, and cost-effective solutions. This identifies and resolves potential problems early. Many maintain in-house tool rooms. These are equipped with modern machines for designing and manufacturing molds and sheet metal tools internally. This reduces reliance on external vendors.

Minimum Order Quantities for OEM Orthodontic Brackets

Minimum Order Quantities (MOQs) are a common aspect of OEM services. Manufacturers set MOQs to ensure production efficiency and cost-effectiveness. These quantities vary significantly among suppliers. They depend on factors like product complexity and material costs. Buyers should discuss MOQs early in the procurement process. This helps align their needs with supplier capabilities. Negotiating MOQs can be possible, especially for long-term partnerships.

Navigating Logistics and Importation of Orthodontic Brackets

Shipping Options and Lead Times for Orthodontic Brackets

Dental professionals must understand shipping options and lead times when importing Orthodontic Brackets. Common choices for international delivery from China include sea freight, air freight, and courier services. Sea freight offers a cost-effective solution for large, heavy shipments, typically over 1 cubic meter or 100kg. It includes Full Container Loads (FCL) for exclusive container use and Less than Container Loads (LCL) for consolidated products. Air freight and courier services suit high-value, low-volume, or urgent deliveries. Courier services like TNT, FedEx, and DHL provide door-to-door service, handling customs and duties, and offer faster delivery. Air freight is similar to LCL, operating port-to-port and requiring a forwarding agent for customs and internal delivery. For small packages under 500kg, courier services often prove more economical than air freight.

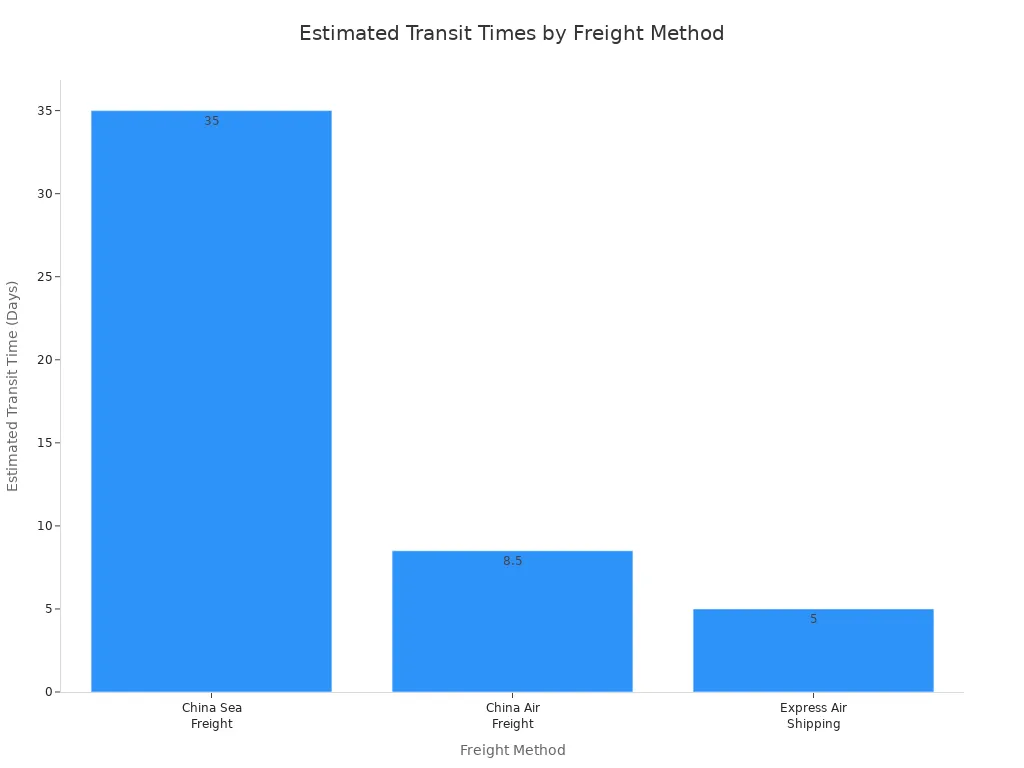

Here is a summary of freight methods and their estimated transit times:

| Freight Method | Best For | Estimated Transit Time | Cost Level |

|---|---|---|---|

| China Sea Freight | Large and heavy shipments | 25 to 45 days | Low |

| China Air Freight | Medium sized shipments and fast delivery | 5 to 12 days | Medium |

| Express Air Shipping | Small parcels and urgent orders | 3 to 7 days | Higher |

Typical sea freight lead times from China include approximately 18 days to Australia, 30 days to the United Kingdom, and about 20-30 days for the USA and Canada.

Customs Regulations and Duties for Orthodontic Brackets

Navigating customs regulations and duties is a critical step in importing medical devices. Importers must comply with the destination country’s specific rules. This often involves proper documentation, product classification, and payment of applicable tariffs. A reliable freight forwarder can assist with customs clearance. They ensure all necessary paperwork is correct and submitted on time. This minimizes delays and avoids unexpected costs. Understanding these regulations beforehand helps ensure a smooth importation process.

Managing International Payments for Orthodontic Brackets

Managing international payments requires careful consideration. Suppliers typically accept various payment methods. These include bank transfers, letters of credit, and online payment platforms. Bank transfers are common for larger transactions. Letters of credit offer security for both buyer and seller. Online platforms provide convenience for smaller or recurring orders. Buyers should discuss payment terms with their suppliers early in the process. This ensures clarity and avoids potential disputes.

Selecting a trusted Chinese Orthodontic Brackets supplier involves evaluating quality standards, certifications, and customization capabilities. Establishing long-term relationships with manufacturers ensures consistent product quality and fosters mutual growth. The future outlook for sourcing from China remains positive, driven by continuous innovation and competitive pricing. Dental professionals gain significant advantages from these strategic partnerships.

FAQ

What quality standards do Chinese orthodontic bracket suppliers follow?

Chinese suppliers often adhere to international quality standards. These include ISO 13485, CE Marking under EU MDR, and FDA listings. These certifications ensure products meet global benchmarks for safety and performance. Manufacturers also implement rigorous in-house quality control.

What types of orthodontic brackets can I source from China?

You can source various types of orthodontic brackets. These include traditional metal, aesthetic ceramic, and innovative self-ligating brackets. Suppliers also offer specialized options like lingual and titanium brackets. Each type caters to different patient needs and treatment preferences.

Are there benefits to placing bulk orders for orthodontic brackets?

Yes, bulk orders offer significant advantages. Manufacturers often provide substantial discounts for larger quantities. This reduces the per-unit cost, improving overall cost-efficiency for dental practices. Bulk purchasing also ensures a consistent supply of materials.

How do suppliers ensure material quality and traceability for brackets?

Suppliers prioritize high-grade, biocompatible materials. They establish strict qualification processes for their material providers. Traceability systems track materials from their origin to the final product. This ensures transparency and confidence in the product’s integrity.

Post time: Dec-26-2025