Modern orthodontics experiences a profound transformation. Material science, digital manufacturing, and integrated smart technologies significantly impact practice. These advancements redefine precision in treatment. They also enhance efficiency, aesthetics, and patient comfort. Professionals now utilize cutting-edge solutions like specialized Orthodontic Brackets. Innovations in Dental Brackets, including advanced Metal Brackets, offer superior performance. The emergence of Self‑Ligating Brackets simplifies procedures. New Arch Wires complement these systems. The ODM Orthodontic Bracket System exemplifies this evolution.

Key Takeaways

- New materials make orthodontic brackets stronger and look better. They also reduce allergic reactions.

- Digital tools like 3D printing help make custom brackets. This makes treatment more exact and faster.

- Smart technologies, like AI, help plan treatments. They also allow doctors to check on patients from far away.

- Modern brackets make treatment faster and more comfortable. They also give better results for patients.

- Doctors should check new bracket technologies carefully. They need to see if they work well and are worth the cost.

Advanced Materials Revolutionizing Orthodontic Brackets

Enhanced Ceramic and Polycrystalline Alumina Brackets

Material science significantly advances the design and performance of orthodontic brackets. Enhanced ceramic and polycrystalline alumina brackets offer superior aesthetics and improved mechanical properties. For instance, 3D-printed customized zirconia INNI-CERA A2 brackets demonstrate 20–30% greater fracture resistance than traditional polycrystalline alumina ceramic brackets (Clarity) and 3D-printed customized polycrystalline alumina LightForce brackets. This enhanced toughness (6.62 ± 0.61 MPa m1/2) helps mitigate wing fractures, a common issue with brittle ceramic materials. However, 3D-printed customized zirconia brackets have relatively lower hardness compared to other ceramics like alumina. Traditional polycrystalline alumina ceramic brackets and LightForce’s 3D-printed customized polycrystalline alumina brackets were 37% and 22% harder, respectively, than 3D-printed customized zirconia brackets (1261 ± 39 HV). While lower hardness might prevent enamel abrasion, it could also lead to bracket wear from arch wires, potentially reducing slot accuracy and necessitating replacement. Zirconia-based ceramic brackets offer superior toughness, which reduces the risk of bracket failure during treatment. These brackets are also less prone to chipping or breaking under stress, indicating improved durability.

Bio-Compatible Alloys and Nickel-Titanium Advancements in Orthodontic Brackets

The development of bio-compatible alloys addresses concerns about allergic reactions and corrosion. These advancements ensure patient safety and comfort.

- Super Austenitic Stainless Steel (SR-50a): This alloy, with high nitrogen (0.331%) and molybdenum (6.77%) content, forms a passive film layer. It offers corrosion resistance comparable to titanium components, addressing nickel-induced allergic reactions. It also provides enhanced strength and better formability.

- 2205 Stainless Steels: These alloys are twice as strong, more corrosion-resistant, and contain less nickel than traditional austenitic stainless steels. They are a preferred option for nickel-sensitive patients.

- Chromium-Cobalt Alloys: Introduced as an alternative to stainless steel, these alloys have a low nickel content (typically up to 0.5%) and a high chromium content (25% to 30%). This reduces the risk of corrosion and makes them suitable for nickel-sensitive patients.

- Titanium and Titanium Alloys (Commercially Pure titanium and Ti-6Al-4V): Known for their superior biocompatibility, excellent corrosion resistance, and low allergic potential, these materials address concerns about metal ion release and potential biological impacts.

- 316 Series Stainless Steel: Specifically, 316 series stainless steel is used for bracket bases due to its high corrosion resistance and low nickel release properties.

- Precious Metal-Coated Alloys (e.g., Gold-Plated Steel): These offer biologically inert surfaces and reduced surface reactivity, though their high cost limits widespread use.

Self-Ligating Orthodontic Bracket Systems for Reduced Friction

Self-ligating bracket systems aim to reduce friction between the archwire and the bracket, potentially leading to faster tooth movement and reduced treatment times. However, clinical data offers a nuanced perspective. A multi-center randomized controlled trial involving 138 subjects compared treatment efficiency between self-ligating (3M SmartClip) and conventional (3M Victory) preadjusted edgewise appliance systems. The study found no significant differences in mean treatment time (25.12 months for SmartClip vs. 25.80 months for Victory) or the number of visits (19.97 for SmartClip vs. 20.37 for Victory). A recent systematic review on self-ligating brackets concluded insufficient evidence exists to suggest that orthodontic treatment is more or less efficient with self-ligating brackets. While initial retrospective studies suggested a significant reduction in treatment time, more recent prospective clinical trials have generally failed to demonstrate similar differences. A study comparing passive SmartClip brackets and conventional Victory series brackets found no significant difference in the time required to complete orthodontic treatment. The degree of tooth displacement, rather than bracket type, was a more significant factor influencing treatment duration.

Nano-Coating Technologies for Improved Hygiene and Durability of Orthodontic Brackets

Nano-coating technologies represent a significant advancement in enhancing the hygiene and durability of orthodontic appliances. These innovative coatings apply at a microscopic level, providing protective layers that actively combat bacterial growth and improve the longevity of the brackets. For instance, nanocoated brackets featuring nitrogen-doped titanium oxide (TiO2) nanoparticles demonstrate strong antimicrobial effects. They effectively target common oral bacteria such as Streptococcus mutans, Lactobacillus acidophilus, Actinomyces viscosus, and Candida albicans. This broad-spectrum action helps maintain a cleaner oral environment around the brackets.

Furthermore, silver nanoparticles play a crucial role when incorporated into adhesives or used as coatings on Orthodontic Brackets. They significantly reduce the adhesion of cariogenic streptococci and plaque. This reduction directly lessens demineralization and the formation of white spot lesions, common complications during orthodontic treatment. Copper oxide nanoparticles also contribute to improved hygiene. Even at low concentrations, when added to orthodontic adhesives, they inhibit the growth of S. mutans. This prevents the proliferation of bacteria responsible for tooth decay.

Another promising development involves halloysite nanotubes (TCN-HNT) loaded with triclosan. When integrated into orthodontic adhesives, these nanotubes enhance long-term antimicrobial efficacy. They achieve this without immediately altering the bonding properties of the adhesive. These nano-coatings collectively contribute to a healthier oral environment, reducing the risk of infection and decay. By actively deterring microbial colonization, they also indirectly support the structural integrity and functional lifespan of the brackets, thereby improving overall durability throughout the treatment period.

Digital Customization and Manufacturing Precision in Orthodontic Brackets

Digital technologies have transformed orthodontic practice. They allow for unprecedented customization and precision in bracket design and placement. This leads to more efficient treatments and superior patient outcomes.

3D Printing for Personalized Orthodontic Bracket Design

3D printing offers significant advancements in creating personalized orthodontic brackets. This technology allows for the production of intricate and complex geometries with micron-level accuracy. For example, Laser Powder Bed Fusion (LPBF) is a 3D printing method that achieves this high level of detail. LightForce utilizes 3D-printed bonding trays to ensure unparalleled accuracy in bracket placement. This method significantly reduces errors compared to traditional manual bonding techniques. The creation of an indirect bonding tray guarantees every bracket is placed precisely where it belongs. This contributes to an accurate and streamlined experience from the very beginning of treatment.

CAD/CAM Integration for Optimal Orthodontic Bracket Placement

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) integration is crucial for precise bracket placement. Orthodontists use specialized software to plan and execute treatments. SolidWorks CAD software, from Dassault Systemes, is often used to construct 3D models of various bracket samples during the design phase. 3Shape offers comprehensive software solutions that assist with bracket placement. These tools complement their clear aligner design software, providing a broad range of orthodontic applications. OrthoAnalyzer software plays a vital role in digital indirect bonding. It imports intraoral scans and aligns them with cone-beam computed tomography (CBCT) data. This step is essential for achieving precise orthodontic bracket placement.

Digital Workflow for Predictable Orthodontic Treatment Outcomes

A fully digital workflow enhances predictability in orthodontic treatment. It begins with accurate digital scans of the patient’s dentition. Orthodontists then use advanced software to simulate tooth movements and plan the ideal final position. This digital blueprint guides the design and manufacturing of custom brackets and wires. The precise placement of brackets, often facilitated by 3D-printed indirect bonding trays, ensures the treatment progresses as planned. This integrated digital approach minimizes chair time and reduces the need for adjustments. It ultimately leads to more predictable and efficient treatment outcomes for patients.

Custom Base Designs for Enhanced Adhesion and Debonding of Orthodontic Brackets

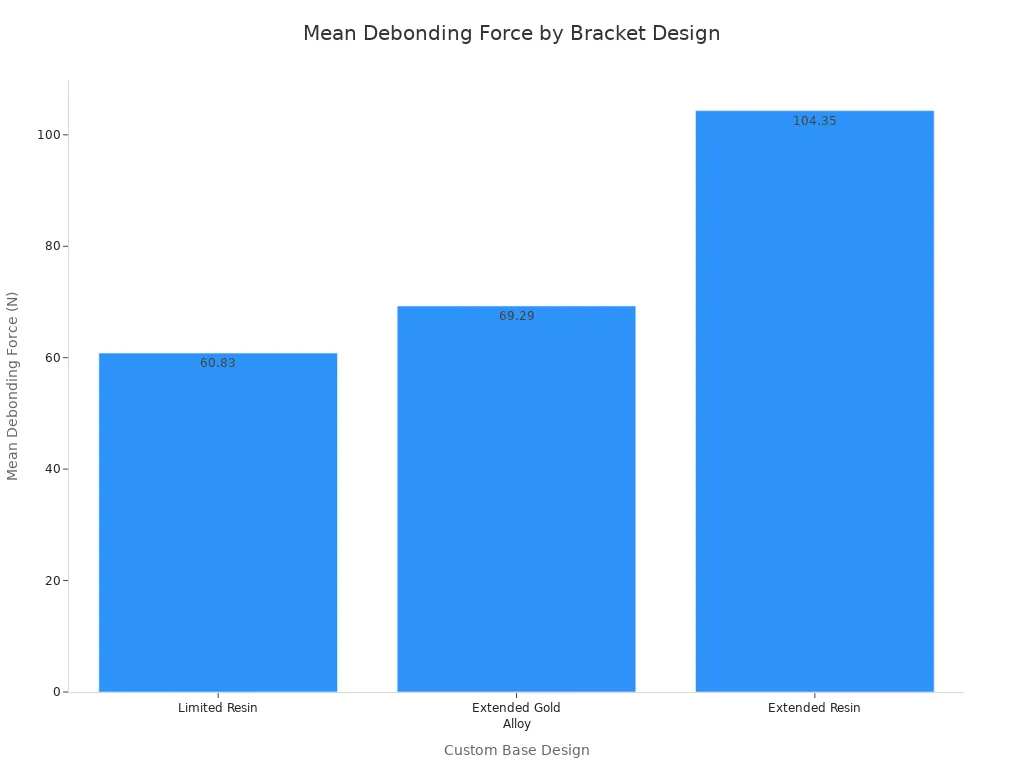

Custom base designs significantly improve the adhesion and debonding characteristics of Orthodontic Brackets. These innovations focus on maximizing the bond strength while ensuring controlled, clean debonding at the end of treatment. Custom base designs increase the bonding surface area. They also optimize bracket bases with micro-retentive designs. These designs individualize the tooth surface and further increase the surface area for adhesive bonding. This approach enhances adhesion strength.

Research demonstrates the effectiveness of various custom base designs. An extended resin base shows significantly higher debonding force compared to both limited resin and extended gold alloy bases. While the extended gold alloy base exhibits a significantly higher adhesive remnant index, the extended resin base achieves the highest overall debonding force. This indicates a stronger, more reliable bond throughout the treatment period.

The following table illustrates the mean debonding forces for different custom base designs:

| Custom Base Design | Mean Debonding Force (N) | Standard Deviation (SD) |

|---|---|---|

| Limited Resin | 60.83 | 10.12 |

| Extended Gold Alloy | 69.29 | 9.59 |

| Extended Resin | 104.35 | 17.84 |

These findings highlight the importance of material and design choices for bracket bases. Professionals can select custom base designs to achieve optimal bond strength. This minimizes unexpected bracket failures during treatment. It also ensures a predictable and efficient debonding process, protecting enamel integrity.

Smart Technologies and Integrated Features in Orthodontic Brackets

AI-Powered Treatment Planning and Orthodontic Bracket Selection

Artificial intelligence significantly advances orthodontic treatment planning and bracket selection. AI algorithms analyze extensive data from patient 3D scans. This includes teeth and facial structure. This analysis creates personalized treatment plans. AI accurately determines the optimal type of braces, such as metal or clear. This ensures a perfect fit and reduces the need for adjustments. AI algorithms also enhance clinical decision-making. They increase precision and reliability in orthodontic diagnostics and treatment strategies. This includes applications in appliance fabrication, bracket setup, clear aligner setup, and digital interpretation. Digital virtual articulators are leveraged for accurate diagnosis and comprehensive treatment planning. Researchers have explored various AI algorithms for specific orthodontic tasks:

| Author (Year) | Algorithms | Purpose |

|---|---|---|

| Xie et al. (2010) | ANN | To predict tooth extraction diagnosis. |

| Jung et al. (2016) | ANN | To predict tooth extraction diagnosis, and extraction patterns. |

Sensor-Equipped Orthodontic Brackets for Real-Time Monitoring

The integration of sensors into orthodontic appliances offers real-time monitoring capabilities. This technology provides valuable data on forces and other parameters. The Orthodontic Force Acquisition System (OFAS) integrates a cross-shaped iontronic sensing array. This system monitors 3D force. It is embedded within clear aligners, not traditional Orthodontic Brackets. The sensing array consists of five independent iontronic sensing units. These units capture both force and torque information. This technology represents a step towards more dynamic and responsive treatment. Currently, no mention exists of temperature sensors integrated into this specific system.

Tele-Orthodontics and Remote Patient Management with Advanced Orthodontic Brackets

Tele-orthodontics leverages smart technologies for remote patient management. This allows orthodontists to monitor patient progress from a distance. Patients can use smartphone apps to send images or videos of their teeth. AI algorithms can analyze these submissions. They flag potential issues or confirm treatment progression. This reduces the need for frequent in-person appointments. It enhances convenience for patients. It also optimizes practice efficiency for professionals. Remote monitoring ensures timely interventions. It maintains treatment predictability. This approach improves patient compliance and overall treatment outcomes.

Data Analytics for Optimized Orthodontic Treatment Protocols

Data analytics transforms orthodontic practice. It provides professionals with powerful tools to refine and optimize treatment protocols. Orthodontists collect vast amounts of patient data. This includes treatment duration, success rates, patient demographics, and specific appliance types used. Advanced algorithms then analyze this comprehensive information. This analysis reveals patterns and correlations. It identifies which treatment approaches yield the most favorable outcomes for different patient profiles.

For example, data analytics can pinpoint the most efficient sequence of archwire changes for specific malocclusions. It can also predict potential challenges based on a patient’s initial presentation. This allows orthodontists to proactively adjust treatment plans. They can minimize complications and reduce overall treatment time. The insights gained from data analysis help personalize treatment strategies. This moves away from a one-size-fits-all approach. Instead, it tailors interventions to individual patient needs.

Furthermore, data analytics supports continuous improvement within a practice. Professionals can track their own success rates for various procedures. They can compare these results against industry benchmarks. This objective evaluation helps identify areas for refinement. It also highlights best practices. Ultimately, data-driven decisions lead to more predictable results. They enhance patient satisfaction and improve practice efficiency. This systematic approach ensures orthodontists consistently deliver high-quality care.

Practical Benefits of Innovative Orthodontic Brackets for Professionals

Improved Treatment Efficiency and Reduced Chair Time with Advanced Orthodontic Brackets

Innovative orthodontic technologies significantly enhance treatment efficiency and reduce chair time for professionals. Customized CAD/CAM bracket systems, for example, lead to shorter treatment durations and less arch-wire bending. This streamlines the treatment process. LightForce 3D-printed brackets also demonstrate superior performance. They reduce average treatment times, scheduled appointments, and emergency visits. These systems minimize bracket debonding incidents. Professionals spend less time on adjustments and repairs. This allows them to manage more patients effectively.

Enhanced Patient Comfort and Aesthetic Options with Modern Orthodontic Brackets

Modern orthodontic brackets prioritize patient comfort and aesthetics. Smaller, less noticeable brackets reduce visibility and enhance comfort. Self-ligating technology eliminates elastic bands, allowing for easier cleaning and adjustments. This also reduces pressure on teeth. Advancements in wire technology ensure consistent pressure, leading to smoother tooth movement and less discomfort. Braces are now designed with smoother materials and smaller brackets. This reduces irritation to gums and cheeks. Customized options, enhanced by 3D printing, ensure a better fit. This minimizes irritation against the tongue and gums, increasing overall patient comfort.

Superior Clinical Outcomes and Predictability with Innovative Orthodontic Brackets

Innovative orthodontic brackets deliver superior clinical outcomes and increased predictability. Customized CAD/CAM bracket systems result in lower American Board of Orthodontics (ABO) scores, indicating better treatment results. Zirconia-printed brackets exhibit much higher toughness compared to alumina brackets. This suggests superior resistance to fractures. Such durability ensures consistent treatment progression without unexpected bracket failures. Professionals can rely on these advanced systems for more predictable and successful patient outcomes.

Streamlined Inventory Management and Cost-Effectiveness of Orthodontic Brackets

Efficient inventory management significantly impacts an orthodontic practice’s financial health. Modern innovations help professionals optimize stock levels and reduce operational costs. Indirect bonding, for example, greatly enhances inventory management. It allows for more precise bracket placement. This method reduces errors. It also minimizes the need for excess stock. Practices can optimize inventory levels. They decrease waste and achieve cost savings. The initial investment in indirect bonding, especially with 3D printed brackets, might be higher. However, it leads to long-term cost reductions. It lowers inventory expenses and minimizes bracket wastage. The custom-made nature of these brackets means practices produce only the necessary quantity. This further streamlines inventory and improves overall efficiency.

A streamlined inventory tracking system offers crucial cost-effectiveness benefits. It provides real-time financial insights. This allows orthodontic practices to monitor spending continuously. They do not wait for annual reports. This enables proactive adjustments and better financial management compared to previous periods.

Automating inventory management in orthodontic practices contributes to cost efficiency through several key performance indicators:

- Time Savings: It reduces the time spent on inventory-related tasks.

- Error Reduction: It decreases stock discrepancies and inaccuracies in orders.

- Cost Efficiency: It lowers operational costs associated with managing inventory.

These advancements allow practices to operate more leanly. They reduce waste and improve their financial bottom line.

Evaluating and Adopting New Orthodontic Bracket Technologies

Assessing Clinical Efficacy and Evidence-Based Research for Orthodontic Brackets

Orthodontic professionals must carefully evaluate new technologies before integration. They assess clinical efficacy through rigorous evidence-based research. This process involves reviewing numerous peer-reviewed studies and clinical trials. These studies provide objective data on bracket performance, durability, and patient outcomes. Professionals prioritize scientific evidence over marketing claims, ensuring new systems offer proven benefits. This approach guarantees patient safety and effective treatment. It also helps avoid adopting unproven or less effective methods. Understanding the long-term effects, success rates, and potential complications of different bracket types is crucial for making informed decisions that benefit both the practice and its patients.

Understanding the Learning Curve for New Orthodontic Bracket Systems

Adopting new orthodontic bracket systems always involves a learning curve for the entire clinical team. Orthodontists and their staff invest significant time and effort in specialized training. Manufacturers often provide comprehensive workshops, online courses, and detailed educational resources to facilitate this transition. Mastering new techniques, bonding protocols, and workflow adjustments is essential for successful integration into daily practice. Initial challenges are common as practitioners adapt to different handling characteristics or system requirements. However, dedicated learning and consistent practice lead to increased proficiency. This ultimately results in more efficient procedures, reduced chair time, and improved patient outcomes, making the initial investment in training highly valuable.

Return on Investment and Long-Term Value of Advanced Orthodontic Brackets

Advanced orthodontic technologies offer a strong return on investment for modern practices. While new systems, including specialized Orthodontic Brackets, may present higher initial costs, they deliver significant long-term value. These innovations often reduce chair time per patient, minimize emergency visits, and streamline overall treatment processes. This directly improves practice efficiency and allows for a higher patient volume without compromising care quality. Enhanced patient comfort and superior clinical results boost patient satisfaction and loyalty. A positive patient experience and strong reputation attract more new patients through referrals. These factors collectively contribute to substantial long-term financial gains, positioning a practice as forward-thinking and patient-focused in a competitive market.

Manufacturer Support and Training Resources for Orthodontic Brackets

Adopting new technologies requires robust support from manufacturers. Professionals must consider the comprehensive resources available when evaluating new systems. Strong manufacturer support ensures a smooth transition and continued success with advanced products. This support extends beyond the initial purchase. It encompasses various critical areas for practice integration.

Manufacturers provide several essential resources:

- Responsive customer service quickly resolves any issues that arise.

- Comprehensive training programs educate orthodontists and staff. These programs cover proper bracket usage, bonding techniques, wire sequencing, and troubleshooting.

- Technical support addresses specific clinical challenges. This ensures practitioners can confidently handle complex cases.

- A strong warranty policy protects against defects or premature failures. This provides peace of mind for the practice.

- Access to clinical research and product updates keeps professionals informed. This ensures they use current and effective techniques.

These resources empower orthodontic practices to maximize the benefits of innovative bracket systems. They minimize potential disruptions during the learning curve. Effective support fosters confidence among clinicians. It also enhances patient care quality. Ultimately, reliable manufacturer backing is crucial for the long-term success and integration of any new orthodontic technology.

Material science, digital manufacturing, and smart technologies converge. This convergence defines the best Orthodontic Brackets for professionals today. Embracing these innovations is crucial. It ensures superior patient care and significant practice advancement. Professionals must adopt a forward-looking perspective. This perspective acknowledges the continued evolution and profound impact of orthodontic bracket technology.

FAQ

What are the main benefits of advanced orthodontic brackets?

Advanced brackets improve treatment efficiency. They reduce chair time for professionals. Patients experience enhanced comfort and better aesthetics. These innovations lead to superior clinical outcomes. They also offer greater predictability in treatment.

How does 3D printing enhance orthodontic bracket design?

3D printing allows for personalized bracket designs. It creates intricate geometries with high accuracy. This technology ensures precise bracket placement. It uses customized indirect bonding trays. This leads to more accurate and streamlined treatment from the start.

What role does AI play in modern orthodontic treatment?

AI analyzes patient 3D scans. It creates personalized treatment plans. AI helps select optimal bracket types. It enhances clinical decision-making. This increases precision and reliability in diagnostics and treatment strategies.

Are self-ligating brackets always faster than traditional ones?

Clinical studies show mixed results. Some initial studies suggested faster treatment. More recent trials often find no significant difference in treatment time. Tooth displacement degree often influences duration more than bracket type.

How do nano-coatings improve bracket hygiene?

Nano-coatings apply at a microscopic level. They actively combat bacterial growth. For example, nitrogen-doped titanium oxide nanoparticles have strong antimicrobial effects. Silver nanoparticles reduce plaque adhesion. This lessens demineralization and white spot lesions.

Post time: Dec-09-2025