For 2025, Denrotary Medical, EKSEN, and SINO ORTHO LIMITED stand out as the primary Chinese manufacturers leading in metal self-ligating brackets. They distinguish themselves through innovation, quality, and strong market presence. The global metal self-ligating brace market is projected to reach approximately $850 million in annual revenue in 2025, highlighting the significant role these companies play. Denrotary Medical Apparatus, a prominent orthodontic bracket supplier, consistently delivers advanced solutions. Professionals often seek high bonding strength brackets, a feature these leaders prioritize. These manufacturers also supply orthodontic brackets for wholesale distributors worldwide. They clearly understand critical design elements, such as what is torque in orthodontic brackets?, ensuring effective treatment outcomes.

Key Takeaways

- Denrotary Medical, EKSEN, and SINO ORTHO LIMITED are top Chinese makers of metal self-ligating brackets for 2025.

- These companies offer new designs and good quality products. They help make braces better for patients.

- Chinese manufacturers follow strict rules for making medical products. This means their braces are safe and work well.

- They use new technology like 3D printing. This helps make braces that fit each person better and work faster.

- Chinese companies offer good prices. This makes advanced braces available to more people around the world.

Overview of Leading Chinese Orthodontic Bracket Suppliers

Identifying Key Players in the 2025 Market

The orthodontic landscape in 2025 clearly shows a few Chinese manufacturers leading the charge in metal self-ligating brackets. Denrotary Medical, EKSEN, and SINO ORTHO LIMITED stand out as the primary innovators and suppliers. These companies have consistently demonstrated their commitment to advancing orthodontic technology. They offer reliable and effective solutions for dental professionals worldwide. Their strong market presence and continuous product development make them key players in this competitive field.

Criteria for Leadership in Metal Self-Ligating Brackets

What makes a company a leader in metal self-ligating brackets? Several crucial factors come into play. First, innovation in bracket design and material science is paramount. Top manufacturers constantly research new alloys and improved mechanics for better patient outcomes. Second, manufacturing precision ensures consistent quality and reliable performance. Brackets must fit perfectly and function flawlessly. Third, a company’s ability to offer cost-effective solutions without compromising quality also defines leadership. Finally, strong customer support and a global distribution network solidify their position. An excellent orthodontic bracket supplier understands these needs.

The Role of Chinese Manufacturers in Global Orthodontics

Chinese manufacturers now play a significant role in the global orthodontics market. They have moved beyond simply producing goods to becoming major innovators. Companies like Denrotary Medical, EKSEN, and SINO ORTHO LIMITED contribute significantly to making advanced orthodontic treatments more accessible worldwide. They invest heavily in research and development, meeting international quality standards and regulatory requirements. This commitment helps drive down costs and introduces new technologies, benefiting both practitioners and patients globally. Their influence continues to grow, shaping the future of orthodontic care.

Denrotary Medical: Innovation and Global Reach as an Orthodontic Bracket Supplier

Denrotary Medical stands out as a premier orthodontic bracket supplier, known for its commitment to innovation and extensive global reach. Located in Ningbo, Zhejiang, China, the company has dedicated itself to orthodontic products since 2012. They consistently deliver advanced solutions to dental professionals worldwide.

Key Metal Self-Ligating Bracket Systems Offered by Denrotary Medical

Denrotary Medical offers a range of sophisticated metal self-ligating bracket systems. These include the Self Ligating Brackets – Passive – MS2, the Self Ligating Bracket – Spherical – MS3, and the Self Ligating Brigating Brackets – Active – MS1. The Passive MS2 brackets, for example, use 17-4 stainless steel materials and MIM technology in their construction. This ensures both durability and precise performance for orthodontists.

Technological Advantages and Unique Features of Denrotary Medical’s Brackets

Denrotary Medical’s brackets boast several technological advantages. They feature both passive and active self-ligation systems. Passive systems use clips and slides to reduce friction, speeding up tooth movement. Active systems, on the other hand, use spring-loaded clips for controlled force, improving treatment precision. The brackets are made from high-grade 17-4 stainless steel, ensuring strength and biocompatibility. You will also find miniaturized bracket profiles, which increase patient comfort by sitting closer to the tooth surface. Integrated archwire slot technology ensures consistent force delivery with an industrial best 0.002 precision error. Some models even include a movable hook, offering greater flexibility. Anti-friction coatings allow smoother wire movement, potentially shortening treatment times.

Market Share and International Recognition of Denrotary Medical

Denrotary Medical has built a strong market presence and earned international recognition through its dedication to quality and innovation. The company operates three automatic orthodontic bracket production lines, capable of producing 10,000 pieces weekly. They have also invested in advanced professional orthodontic production equipment and testing instruments from Germany. This commitment to high manufacturing standards helps them meet global demand and maintain their reputation as a reliable supplier in the orthodontic industry.

EKSEN: Quality and Cost-Effectiveness in Orthodontic Brackets

Overview of EKSEN’s Leading Metal Self-Ligating Bracket Lines

EKSEN has established itself as a reliable provider of orthodontic solutions, including a strong lineup of metal self-ligating brackets. They offer various designs that cater to different orthodontic needs. These brackets aim to provide efficient tooth movement and patient comfort. EKSEN focuses on creating products that dental professionals can trust for consistent performance. Their bracket lines often feature innovative designs that help reduce treatment time and improve overall outcomes for patients.

Manufacturing Standards and Quality Control of EKSEN

EKSEN takes its manufacturing standards seriously. The company adheres to CE certification requirements, ensuring its products meet the strict safety and quality standards of the European Union. EKSEN also complies with ISO 13485:2016. This shows their commitment to maintaining a strong quality management system. Regular audits and rigorous testing further prove the reliability of EKSEN’s products. These steps ensure every bracket meets high standards before reaching an orthodontist’s office. This dedication to quality makes EKSEN a trusted orthodontic bracket supplier.

Value Proposition and Market Positioning of EKSEN

EKSEN positions itself in the market by offering high-quality, certified products. They provide CE-certified and FDA-listed metal and ceramic brackets. This emphasizes their compliance with international standards. Their products are known for durability and precision. While these certifications and quality make EKSEN a reliable choice, their pricing tends to be a bit higher compared to some other manufacturers. This reflects the premium quality and their commitment to regulatory adherence. EKSEN aims to deliver value through superior product performance and reliability, rather than just the lowest price.

SINO ORTHO LIMITED: Emerging Leader with Specialized Solutions

SINO ORTHO LIMITED is quickly becoming a significant player in the metal self-ligating bracket market. This company distinguishes itself through innovative designs and a clear focus on specific orthodontic needs. They offer solutions that enhance both treatment efficiency and patient comfort.

Distinctive Metal Self-Ligating Bracket Innovations from SINO ORTHO LIMITED

SINO ORTHO LIMITED has made significant strides in metal self-ligating bracket technology. They offer a range of innovative features designed to improve treatment outcomes and patient comfort. Their brackets incorporate both passive and interactive self-ligating technologies. Passive systems reduce friction, which allows for faster tooth movement and potentially shorter treatment times. Interactive systems provide precise control, especially crucial during the final stages of orthodontic treatment.

SINO ORTHO LIMITED also focuses on patient comfort. They design their brackets with a low profile and smooth, rounded edges. This minimizes discomfort and reduces irritation to soft tissues. For orthodontists, the brackets feature an easy-to-open/close mechanism, simplifying wire changes. They also include a nickel-titanium clip, ensuring consistent and reliable ligation throughout treatment. Furthermore, the brackets boast a vertical slot for auxiliary attachments and precise torque control. SINO ORTHO LIMITED uses advanced manufacturing techniques like MIM (Metal Injection Molding) technology for high precision and strength, and laser welding technology for strong, reliable bond strength. A sandblasted base enhances bond strength, preventing debonding. Removable hooks offer flexibility for various treatment mechanics, and an identification system simplifies placement.

Focus on Specific Orthodontic Needs by SINO ORTHO LIMITED

SINO ORTHO LIMITED designs its metal self-ligating brackets to address specific orthodontic needs effectively. Their focus on reducing friction with passive self-ligating technology directly benefits patients needing faster initial alignment. The interactive technology provides orthodontists with the fine-tuned control necessary for complex cases and precise finishing. This dual approach ensures versatility.

The company also prioritizes patient experience. Their low-profile design and smooth edges significantly reduce irritation, making the orthodontic journey more comfortable. This is a key consideration for long-term wear. For the clinician, features like the easy-to-open/close mechanism and the identification system streamline the treatment process, saving valuable chair time. The inclusion of a vertical slot and removable hooks gives orthodontists greater flexibility in applying various treatment mechanics, allowing them to customize solutions for individual patient requirements.

Growth Trajectory and Future Outlook for SINO ORTHO LIMITED

SINO ORTHO LIMITED shows a promising growth trajectory in the metal self-ligating bracket market. While specific growth percentages for the company are not publicly available, the overall metal self-ligating brace market is projected to grow significantly, with an estimated CAGR of around 8% over the next few years and 8.5% from 2025 to 2032. SINO ORTHO LIMITED, as a Chinese manufacturer, has gained considerable traction by offering cost-effective self-ligating braces. This strategy particularly appeals to emerging markets.

The company’s future outlook involves strategic international expansion. They plan to collaborate with local distributors to increase their global market share. This approach helps them reach a wider audience and establish a stronger presence worldwide. As an orthodontic bracket supplier, SINO ORTHO LIMITED continues to invest in innovation and quality, positioning itself for sustained growth in the competitive global orthodontic landscape.

Key Factors Driving Leadership in 2025 for Orthodontic Bracket Suppliers

Material Science Advancements in Chinese Metal Self-Ligating Brackets

Chinese manufacturers are pushing boundaries in material science for metal self-ligating brackets. They constantly explore new alloys and composites. These advancements lead to stronger, more biocompatible, and aesthetically pleasing brackets. For example, new stainless steel alloys offer enhanced corrosion resistance and durability. This means brackets last longer and perform better throughout treatment. Manufacturers also focus on reducing friction within the bracket system. This allows teeth to move more efficiently and comfortably for patients. These material innovations directly contribute to better treatment outcomes and patient satisfaction.

Manufacturing Precision and Automation in Bracket Production

Leading Chinese manufacturers achieve exceptional precision through advanced automation. They use robotic welding for strong and accurate OEM bracket production. This ensures consistent quality. Strict quality assurance measures are in place, including certifications like ISO 9001. They also perform non-destructive testing, weld inspection, and stress analysis to maintain dimensional accuracy and material integrity. Many suppliers, such as Guangdong Hwashi Technology, boast 100% on-time delivery. This shows their strong operational control.

China has several key hubs for this advanced manufacturing:

- Shandong Province hosts over 10 specialized robotics and welding equipment manufacturers.

- Guangdong Province is a hub for high-precision automation parts.

- Jiangsu Province is known for large-scale industrial automation facilities.

- Hebei Province emerges as a center for intelligent machinery with growing robotic welding applications.

Manufacturers widely use advanced 5-axis CNC machining centers. These machines produce highly complex geometries in a single setup, boosting both precision and efficiency. Sophisticated CAD/CAM platforms also ensure a seamless transition from digital design to physical parts. This is crucial for maintaining design intent and adhering to precise specifications.

Research and Development Investment by Leading Chinese Manufacturers

Chinese manufacturers understand the importance of continuous innovation. They invest heavily in research and development (R&D). This commitment allows them to explore new technologies and refine existing designs. R&D teams work on improving bracket mechanics, material properties, and patient comfort. They also focus on integrating digital orthodontics and AI into bracket design. This investment helps them stay competitive in the global market. It also ensures they continue to offer cutting-edge solutions to orthodontic professionals worldwide. Their dedication to R&D drives their leadership in the industry.

Regulatory Compliance and Certifications for Orthodontic Products

Orthodontic product manufacturers must follow strict rules. These rules ensure product safety and quality. Meeting these standards helps companies sell their products globally. It also builds trust with dental professionals and patients.

For example, companies targeting the Chinese market need CFDA (China Food and Drug Administration) approval. This certification confirms products meet China’s safety and quality standards. If a manufacturer wants to sell in Australia, they must get TGA (Therapeutic Goods Administration) approval. This shows compliance with Australian safety and performance standards. Similarly, ANVISA (Agência Nacional de Vigilância Sanitária) is essential for entering the Brazilian market. This ensures products meet Brazil’s health and safety requirements.

Beyond market-specific approvals, general standards are also crucial. Material Safety and Biocompatibility Standards are vital for patient safety. These standards ensure materials do not cause bad reactions. ISO 10993 is a key standard for checking how well medical devices work with the body. Manufacturers also follow Good Manufacturing Practices (GMP). These guidelines ensure consistent production processes. They guarantee quality and safety for orthodontic brackets.

Furthermore, Quality Control and Traceability are very important. These practices help identify any defects. They also ensure product consistency. Manufacturers can track materials through every production step. Finally, Ethical and Environmental Compliance matters. This includes getting materials ethically and using sustainable practices. Companies minimize waste and use renewable energy. All these efforts ensure patients receive safe and effective orthodontic products.

Choosing the Right Chinese Orthodontic Bracket Supplier: Considerations for 2025

Selecting the best Chinese orthodontic bracket supplier requires careful thought. You want a partner who delivers quality, reliability, and flexibility. Here are key factors to consider for 2025.

Assessing Product Quality and Durability of Brackets

Product quality and durability are paramount for orthodontic brackets. You need to ensure the brackets withstand the rigors of treatment. Manufacturers perform several tests to guarantee this.

- Durability Testing:

- Stress and fatigue testing simulates chewing forces. This ensures the brackets maintain structural integrity over time.

- Wear and tear resistance measures performance under friction. This prevents material degradation from orthodontic wires.

- Biocompatibility Testing:

- Safety for oral tissues assesses if materials release harmful substances. This protects patients during long-term contact.

- Allergic reaction testing identifies potential risks. It checks for allergic responses to bracket materials in oral conditions.

- Corrosion Resistance Testing:

- Simulation of oral conditions evaluates how brackets withstand degradation. They immerse brackets in solutions mimicking saliva and acidic environments.

- Maintenance of structural integrity ensures brackets remain durable. This prevents weakening from corrosion, which could lead to fractures.

Evaluating Supplier Reliability and Customer Support

A reliable supplier offers more than just products. They provide strong support and consistent service. Consider these aspects when evaluating an orthodontic bracket supplier:

| Service Category | Basic Offering | Standard Industry | Premium Level | Verification Method |

|---|---|---|---|---|

| Warranty Duration | 1 year limited | 2 years comprehensive | 3+ years full coverage | Written warranty documentation |

| Technical Support | Email only, 48h response | Phone/email, 24h response | 24/7 multilingual support | Test response times before commitment |

| Training Resources | Basic product manuals | Video tutorials + docs | Live training sessions | Sample training materials review |

| Customization Options | Color variations only | Logo + minor mods | Full OEM customization | Customization portfolio exam |

| Shipping & Logistics | Standard shipping only | Tracking + insurance | Expedited global delivery | Shipping timeline guarantees |

Always conduct thorough reference checks. Contact current clients to understand their real experiences. Negotiate terms carefully, balancing cost with value. Ensure service level agreements cover delivery, quality, and support. Build strategic partnerships based on shared goals and communication. Continuously monitor performance through regular reviews.

Understanding Customization Options and Supply Chain Efficiency

Many Chinese suppliers offer extensive customization for metal self-ligating brackets. You can find manufacturers specializing in customized lingual self-ligating brackets. This confirms that tailored solutions are readily available. Suppliers often state that all customized products come with high quality and competitive prices. This indicates customization is a standard offering for their metal brackets. Efficient supply chains ensure timely delivery and consistent product availability. Look for suppliers with robust logistics and clear communication channels. This helps you maintain smooth operations in your practice.

Comparative Analysis of Leading Chinese Orthodontic Bracket Manufacturers

Feature Comparison: Denrotary Medical vs. EKSEN vs. SINO ORTHO LIMITED

When you look at the top Chinese manufacturers for metal self-ligating brackets, each one brings something special to the table. Denrotary Medical focuses on innovation and reaching customers worldwide. They offer advanced bracket systems with unique features like anti-friction coatings and precise archwire slots. EKSEN emphasizes quality and cost-effectiveness. They ensure their brackets meet strict international standards like CE and ISO 13485. SINO ORTHO LIMITED stands out with specialized solutions. They design brackets for specific orthodontic needs, prioritizing patient comfort with low profiles and smooth edges.

Price Point and Accessibility Across Manufacturers

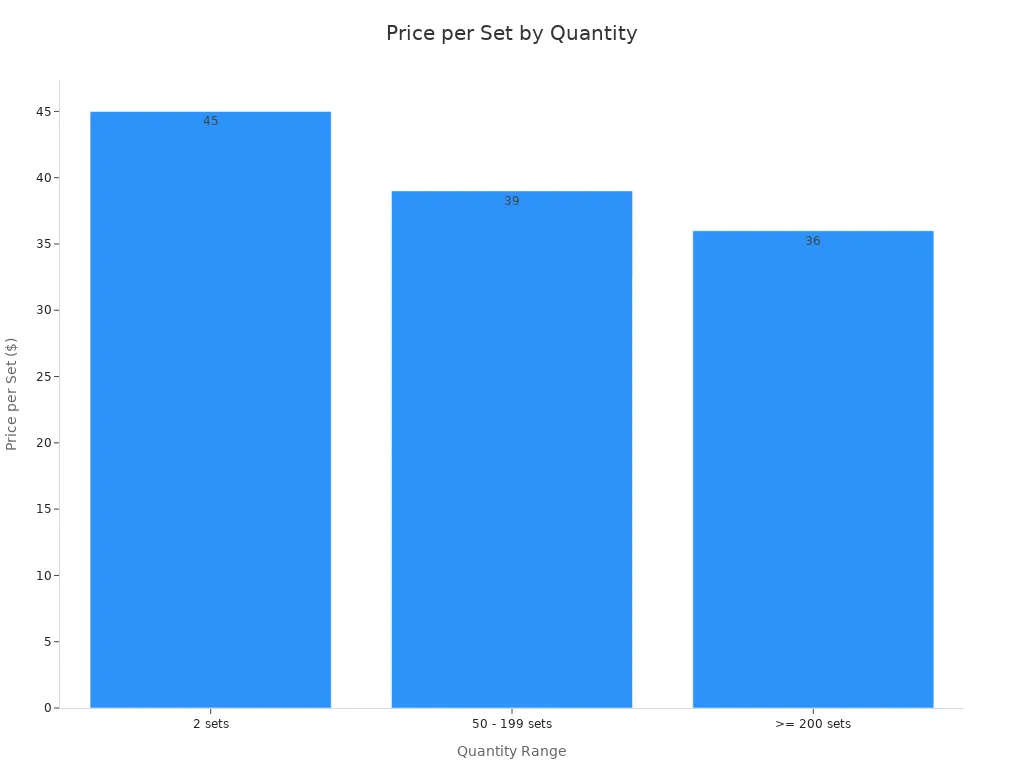

Understanding the cost helps orthodontists make choices. For Denrotary Medical’s metal self-ligating brackets, prices vary based on the quantity you order.

| Quantity | Price per set |

|---|---|

| 2 sets | $45 |

| 50 – 199 sets | $39 |

| >= 200 sets | $36 |

You can see how buying more sets brings the price down.  Unfortunately, specific pricing details for EKSEN and SINO ORTHO LIMITED are not available in the provided information. Generally, competitive pricing makes advanced orthodontic treatments more accessible to a wider range of patients globally.

Unfortunately, specific pricing details for EKSEN and SINO ORTHO LIMITED are not available in the provided information. Generally, competitive pricing makes advanced orthodontic treatments more accessible to a wider range of patients globally.

Customer Feedback and Professional Endorsements

Customer feedback and professional endorsements play a big role in a manufacturer’s reputation. Orthodontists often share their experiences with bracket performance, ease of use, and patient comfort. Positive reviews build trust and show a product’s reliability. When a respected professional endorses a bracket system, it signals quality and effectiveness to others in the field. These endorsements often highlight a manufacturer’s commitment to innovation and patient care. They help new customers choose the right orthodontic bracket supplier.

Future Trends in Chinese Metal Self-Ligating Brackets

Integration of Digital Orthodontics and AI in Bracket Design

The future of metal self-ligating brackets will see significant integration of digital orthodontics and artificial intelligence (AI). This brings greater efficiency and precision to treatment.

The future is about even greater efficiency and precision. Expect continued advancements in AI-driven case planning, more streamlined in-office digital workflows, and further optimization of bracket and wire interactions. Custom digital systems will continue to evolve toward greater ease of use and integration, making them the standard of care driven by doctors, their teams and their patients, rather than an optional upgrade. The most exciting innovations will be those that empower orthodontists to deliver faster, more predictable results while maintaining full control over treatment mechanics.

AI-guided treatment planning and 3D-printed digital indirect bonding trays elevate efficiency. They allow for optimal bracket placement. This technology significantly shortens bonding times to five minutes or less of doctor time. Custom prescriptions and brackets provide the right torque for exact movements. This achieves ideal occlusion and aesthetic outcomes. The shift toward customization is a necessity. Patients demand shorter treatment times and fewer in-office visits without compromising results. AI software analyzes patient scans to forecast tooth movements. This helps orthodontists select the most effective treatment approach. It reduces the likelihood of extended treatment times or corrections.

Sustainability and Eco-Friendly Manufacturing Practices

Chinese manufacturers increasingly adopt sustainable and eco-friendly practices. They aim to reduce their environmental footprint. This commitment aligns with global efforts for greener production.

| Conventional Practice | Sustainable Practice | Benefit |

|---|---|---|

| Orthodontic accessories sold in conventional packaging | Brackets sold in receptacles with a larger quantity of accessories, made of recyclable product | Eliminates plastic packaging, replaced with biodegradable materials |

| Adhesive systems with acid etching | Self-etching adhesive systems | Lowers water consumption due to no need for washing and drying, with same clinical efficacy |

| Conventional brackets | Self-ligating brackets | Reduces chair time and eliminates the use of elastomers |

| Use of non-sterilizable orthodontic archwires | Use of orthodontic archwires capable of being sterilized | Reduces discard of solid residues that may have been contaminated |

| Re-bond new brackets when they de-bond during treatment | Recycle brackets by roughening their base with aluminum oxide and performing new bonding | Eliminates solid residues, extending useful life of brackets |

| Light polymerization with conventional halogen or LED appliances | Ultra-rapid LED light | Shorter chair time and uses low energy consumption LED lamp |

| Use of synthetic intermaxillary elastics | Use of elastics made of latex | Promotes cultivation of trees as latex is extracted from them |

| The use of a new mini-implant in a patient who needs to replace the one in use | Sterilization and use of the same mini-implant that was removed in the same patient | Reduces solid residues from mini-implants |

These practices range from using recyclable packaging to adopting self-etching adhesive systems. They also include recycling brackets and sterilizing archwires. These efforts reduce waste, conserve resources, and promote a healthier environment.

Expanding Global Market Penetration Strategies for Chinese Suppliers

Chinese suppliers will continue to expand their global market penetration. They actively seek new opportunities worldwide. Manufacturers form strategic partnerships with international distributors. This helps them reach more orthodontists and patients. They also focus on meeting diverse international regulatory standards. This ensures their products are accepted in various countries. Competitive pricing combined with high-quality products makes Chinese manufacturers attractive to global buyers. This strategy solidifies their position as major orthodontic bracket suppliers.

Advancements in Bracket Aesthetics and Patient Comfort

Metal self-ligating brackets continue to evolve, focusing on both how they look and how comfortable they feel for patients. Manufacturers often craft these brackets from strong, high-quality stainless steel. This material ensures durability throughout the treatment period. It also helps the brackets maintain a subtle appearance in the mouth.

For patient comfort, the innovative sliding mechanism of self-ligating systems makes a big difference. This design reduces friction and pressure on the teeth. This leads to a smoother treatment experience for the patient. It can also mean shorter treatment durations and fewer adjustments at the orthodontist’s office. This design helps secure the archwire, which significantly reduces friction and pressure on the teeth. This can lead to shorter treatment times and a more comfortable experience overall.

The Impact of 3D Printing on Orthodontic Bracket Production

3D printing technology has greatly changed the orthodontic industry. It allows for the production of customized brackets and aligners. These personalized appliances fit each patient’s unique dental structure perfectly. This leads to more efficient and effective treatment processes. They also make patients more comfortable by reducing irritation and improving the overall fit.

Furthermore, 3D printing helps create indirect bonding trays. These trays are custom-made to place brackets on teeth precisely and accurately. This saves time during the bonding process and ensures optimal placement for better treatment outcomes. This level of precision and customization raises the standard of care. It results in more efficient and effective treatments. However, metal 3D printing for high-volume items like brackets has faced challenges. Studies show limitations such as greater variation in slot size and a lack of cost-effectiveness compared to other 3D printed orthodontic appliances.

Denrotary Medical, EKSEN, and SINO ORTHO LIMITED will lead the Chinese market for metal self-ligating brackets in 2025. Each company offers distinct strengths in innovation, quality, and specialized solutions. These manufacturers are top choices for orthodontic professionals seeking reliable and advanced metal self-ligating brackets. Their continued growth and technological advancements underscore China’s significant role as an orthodontic bracket supplier in the global market. They provide excellent options for practices worldwide.

FAQ

Which Chinese manufacturers lead in metal self-ligating brackets for 2025?

Denrotary Medical, EKSEN, and SINO ORTHO LIMITED lead the Chinese market. They stand out for their innovation, quality, and strong market presence. These companies offer advanced solutions for orthodontic professionals worldwide.

What makes Chinese metal self-ligating brackets a good choice?

Chinese manufacturers offer high-quality, cost-effective solutions. They invest in advanced technology and adhere to international standards. This makes their brackets reliable and accessible globally. They also focus on patient comfort and efficient treatment.

Do these Chinese manufacturers meet international quality standards?

Yes, leading Chinese manufacturers like EKSEN hold CE and ISO 13485 certifications. Denrotary Medical uses advanced German equipment. These certifications and practices ensure their products meet strict global safety and quality requirements.

How does 3D printing impact orthodontic bracket production in China?

3D printing allows for customized brackets and aligners. This technology improves precision and patient comfort. It also helps create indirect bonding trays for accurate bracket placement. This leads to more efficient and effective treatments.

Are Chinese metal self-ligating brackets affordable?

Chinese manufacturers often provide competitive pricing. For example, Denrotary Medical offers lower prices for larger orders. This makes advanced orthodontic treatments more accessible to a wider range of patients globally.

Post time: Dec-17-2025